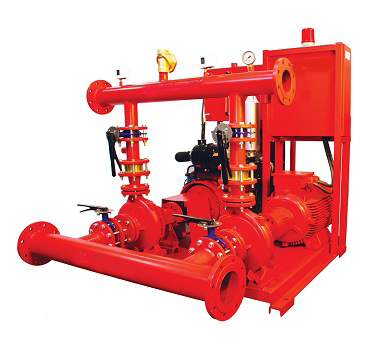

Fire Fighting Pump Sets For DOP-SB03726-NFPA-20

Short Description:

Fire fighting pumps in our product portfolio are mainly composed of one or more main fire fighting pump(s) with electric motor and/or diesel engine drive and a jockey pump suitable for the main pump(s) according to NFPA 20.

Electric motor driven main fire pump system :

Usually, end suction or split case pumps are used. Use of multi stage pumps with horizontal or vertical shafts or vertical shaft turbine pumps are also common. In multipump systems, the electrical controllers for the pumps are installed in a single controller enclosure. It is possible to provide the controllers in seperate enclosures for each pump on request. The controllers provide weekly test function. A seperate alarm device for signalling various states in the fire system is delivered together with the system. There are recirculation relief valves installed on the discharge side of the main pumps to redirect the fluid to the suction tank in case of operation with a closed delivery valve.

Diesel Engine Driven Main Fire Pump System :

Usually, end suction or split case pumps are used. Use of multistage pumps with horizontal shafts are also common. There is a recirculation relief valve installed on the discharge side of the pump to redirect the fluid to the suction tank in case of operation with a closed delivery valve. Pump is delivered together with the electrical controller, starting battery, fuel tank, exhaust manifold and an alarm device for signalling various states in the fire system.

Jockey Pump System :

Jockey pump systems are used to prevent the main pumps from starting during small flow rates caused by leaks etc. They are actually self contained single pump boosters made of a vertical shaft multi stage pump. These are delivered together with a level fl oater for dry running protection and a shock absorbing expansion tank of 100 liters capacity.

Main Fire Fighting Pump Types

There are 4 pump type via NFPA conditions for fire fighting systems :

• Horizontal End Suction Pumps,

• Horizontal Split Case Pumps,

• Vertical Inline Type Pumps,

• Vertical Tribune Type Pumps

End suction type fire pumps mounted on a baseplate are single stage pumps developed for a wide range of applications and their body can be axially split for maintenance. Pump body is of a form that prevents formation of air pockets. The bearing bracket is easily disassembled for maintenance, the mechanical seal is of self lubricated design.

Split case pumps are manufactured to maximize the efficiency and to minimize turbulence by providing laminer flow in the suction eye of the impeller. They are ideal for use in limited spaces and replacing already installed systems with their compact sizes. Main fire pumps may be delivered in complete cast iron,

• No permitted self priming systems for surface pumps. If need, you have to use tribune type pumps.

Capacity :

• Maximum head of pump must be 140% of nominal head at most.

• Pumps selection should be made according to its ability to operate at nominal flow rate of 150%. Also, at this point, minimum head must be 65% of nominal head.

Materials:

• Seal is soft package rolling as to be 5 times.

• In design of fire fighting pumps, fluid speed is maximum 3 m/sec. To reduce velocity of fluids, eksantric and concantric reduction must be used after inlet and outlet of pumps.

• Each pumps have control panel seperately.

• Pump body should be GG-25 cast iron or GGG 40 sphere cast iron depends on pressure level.

• Pump impeller should be bronze or stainless steel to resist of corrosion.

• Pump shaft should be AISI 316 stainless steel.

Product Material

- Seal is soft package rolling as to be 5 times.

- In design of fire fighting pumps, fluid speed is maximum 3 m/sec. To reduce velocity of fluids, eksantric and concantric reduction must be used after inlet and outlet of pumps.

- Each pumps have control panel seperately.

- Pump body should be GG-25 cast iron or GGG 40 sphere cast iron depends on pressure level.

- Pump impeller should be bronze or stainless steel to resist of corrosion

- Pump shaft should be AISI 316 stainless steel.

Download Full Catalogue

Featured Products